Valves

Decades of experience – in every valve

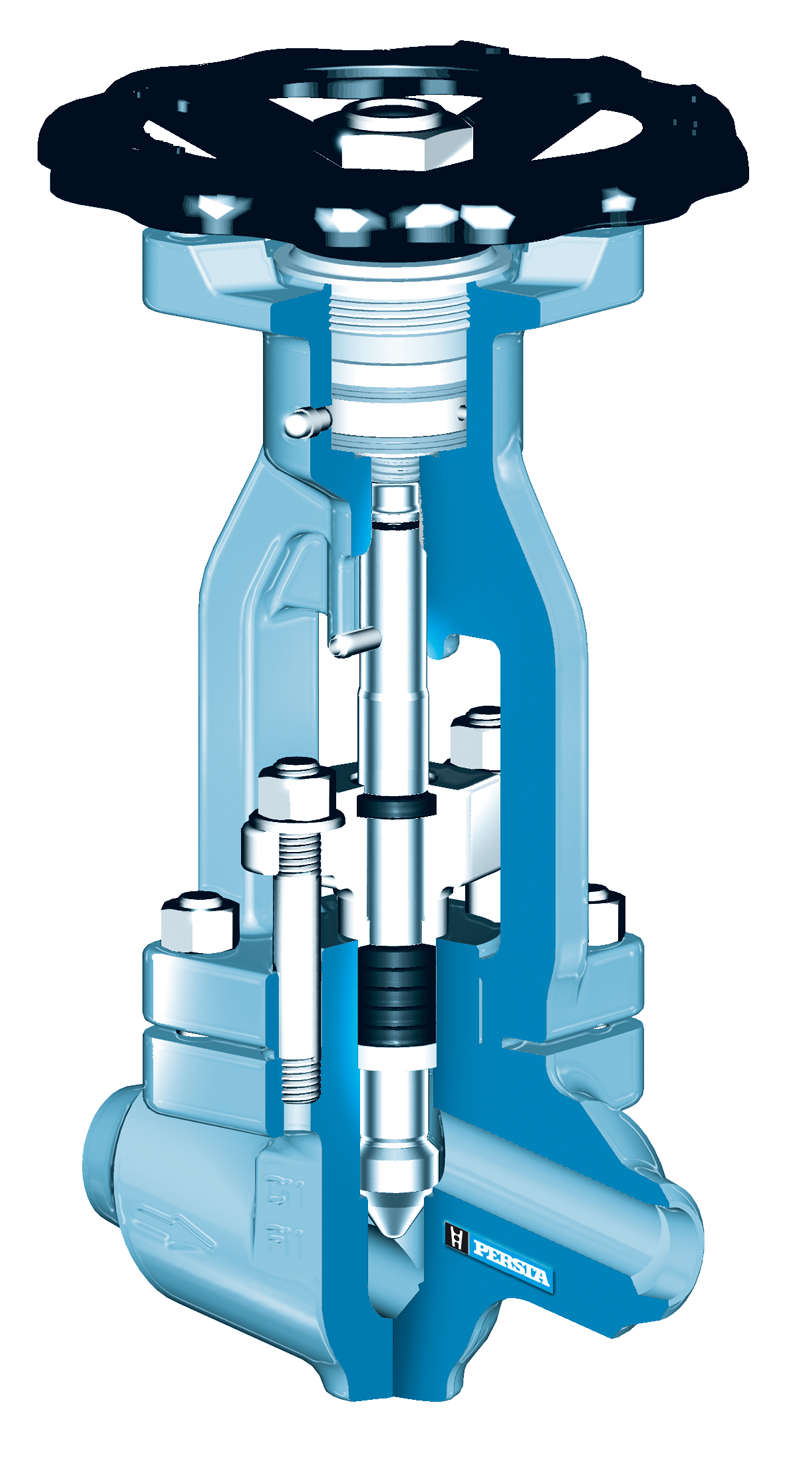

Several decades of experience have gone into each PERSTA valve and this also applies to shut-off valves and lift-check valves. Nevertheless, we are still acquiring new knowledge with regard to leak-tightness, wear and durability, which we continue to incorporate into the design and production of our valves. This not only makes us the first point of contact for plant construction companies and customers from power plant engineering, for whom durability and quality are a priority, but also enables us to achieve a high level of implementation of individual customer requests and requirements. From a combination of a lift-check valve and a shut-off valve to a bellow seal, throttle disc or special system locking mechanism – nothing is a problem for PERSTA.

Low-maintenance and fault-free

The fact that our valves are regarded as particularly low-maintenance and as functioning without faults is mainly down to the material used. We use steel casings that are not cast but are forged next door in the halls of our parent company, SIEPMANN-WERKE. This means that we know our products inside out – from the first hammer blow to shape the casing to the final turn of the bolt in the casing cover. Our customers appreciate this end-to-end manufacturing because it translates directly into lower maintenance costs and a longer service life.

Materials

- 1.0460 / A105

- 1.0619 / A216WCB

- 1.5415

- 1.7335 / A182 F12

- 1.7357

- 1.7383 / A182 F22

- 1.6368

- 1.4903 / A182 F91

- 1.4901 / A182 F92

- 1,4571

- 1.4581

- 1.4550 / A182 F347H

Other materials upon request.

Media

Water, steam, gas, oil and other aggressive and non-aggressive media.

Pressure

Up to PN 630

Nominal size

Up to DN 250

Temperature

Up to +650°C