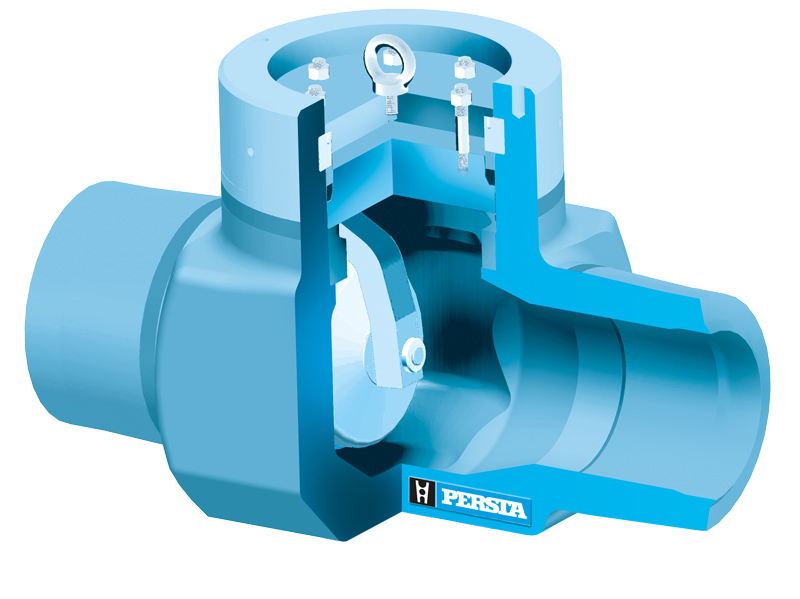

Swing check valves

Backflow eliminated

Wherever a PERSTA swing check valve is used, the medium can only go in one direction. It is our responsibility to eliminate backflow. The quality of our valves also has other advantages because it means that they are extremely easy to use and incredibly low-maintenance. We achieve this quality through forged steel from SIEPMANN-WERKE and the work of our engineers who know their trade. The fact that our valves are fully manufactured in house means that we can be sure that each processing step is performed with maximum precision and care. Our casings meet every specification, right down to the last millimetre of forged steel, and every bolt in our valves is tightened to the right torque. This is how we guarantee above-average durability, regardless of whether the valve is integrated into the pipe system by means of a flange or weld seam or as a special connection.

Variants for every application

The wide range of possible pressure levels and materials, and the numerous different versions enabling flexible application mean that our swing check valves have been tried and tested in every sector. Inside disc hinge pin, pressure sealing bonnet, lever and weight, closing spring or damping cylinder – we always supply our customers with the desired version. Free-flow swing check valves with pneumatic or hydraulic drives also find their way from Warstein to power plants and refineries around the world.

Materials

- 1.0460 / A105

- 1.0619 / A216 WCB

- 1.0425 / A516Gr.60

- 1.5415

- 1.7335 / A182 F12

- 1.7383 / A182 F22

- 1.6368

- 1.4903 / A182 F91

- 1.4901 / A182 F92

- 1.4581

- 1.4571

Other materials upon request.

Media

Water, steam, oil, gas and other non-aggressive media.

Pressure

Up to PN 630

Nominal size

Up to DN 800

Temperature

Up to +650°C